The company and Xiamen Xiangsheng Nickel Industry Co., Ltd. PT.OBSIDIAN STAINLESS STEEL undertook the installation and supply of 35 sets of reducer equipment for the ironmaking project of Indonesia's second phase of 3 million tons of stainless steel integrated integrated project in early 2016 and early 2020.

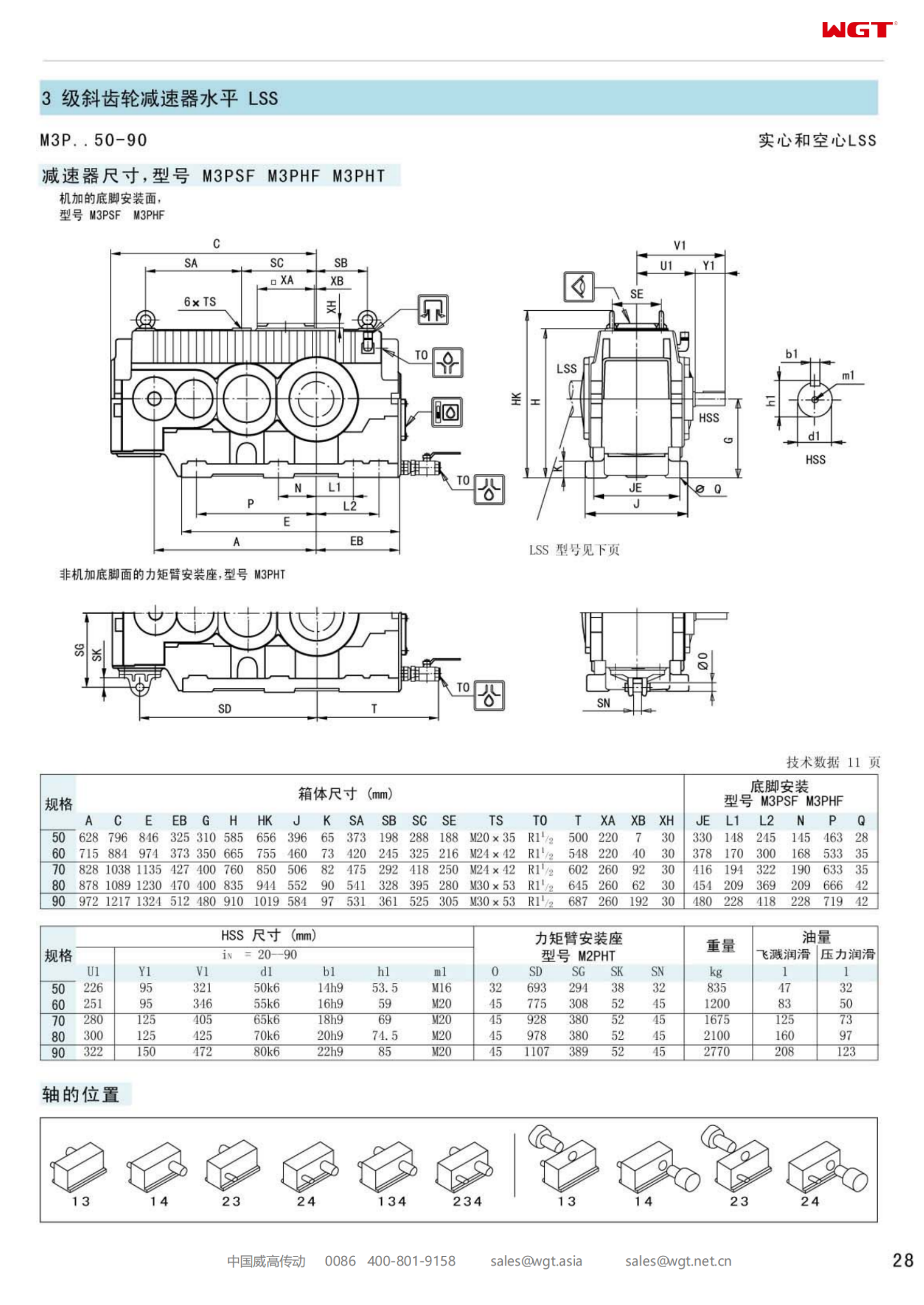

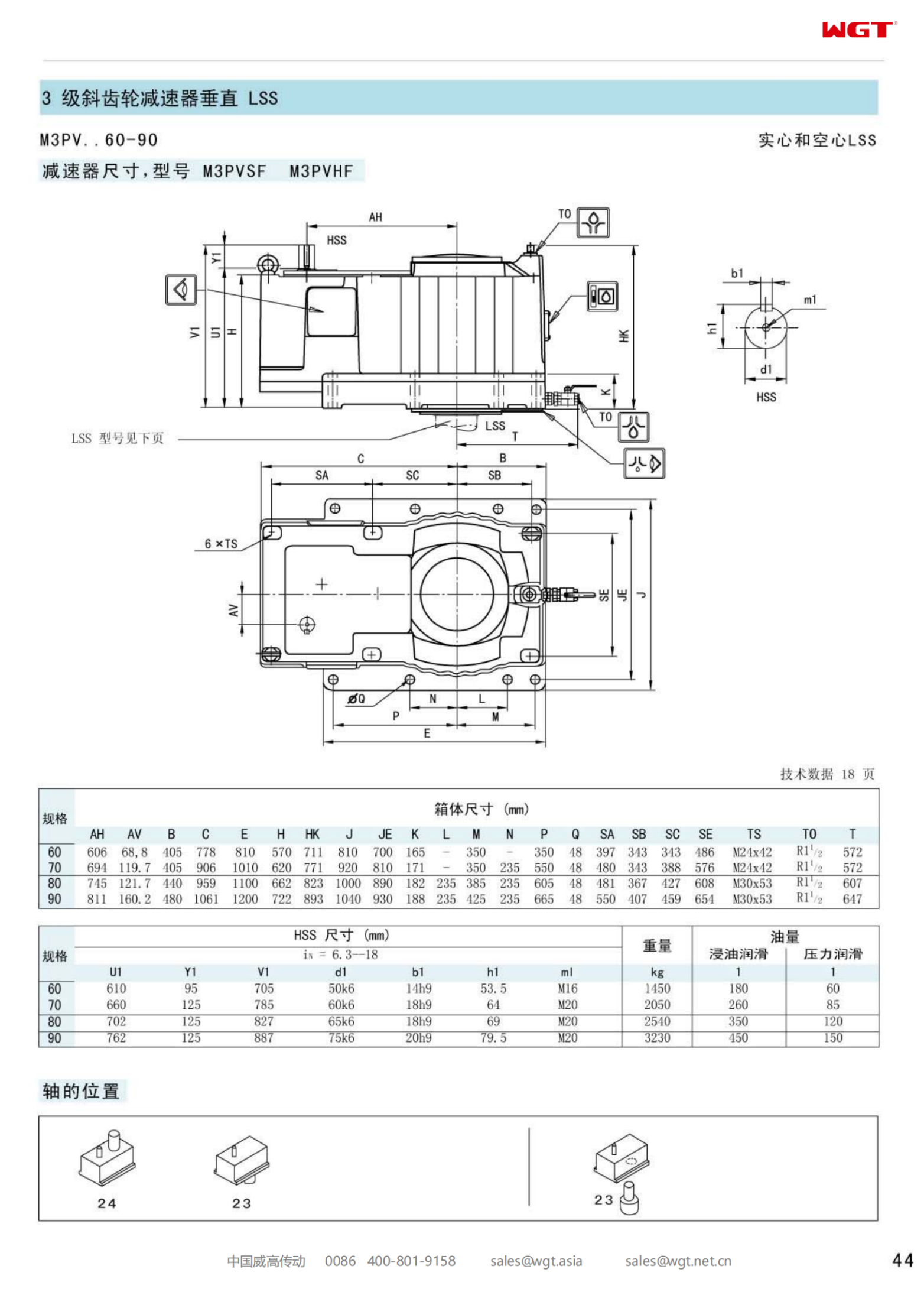

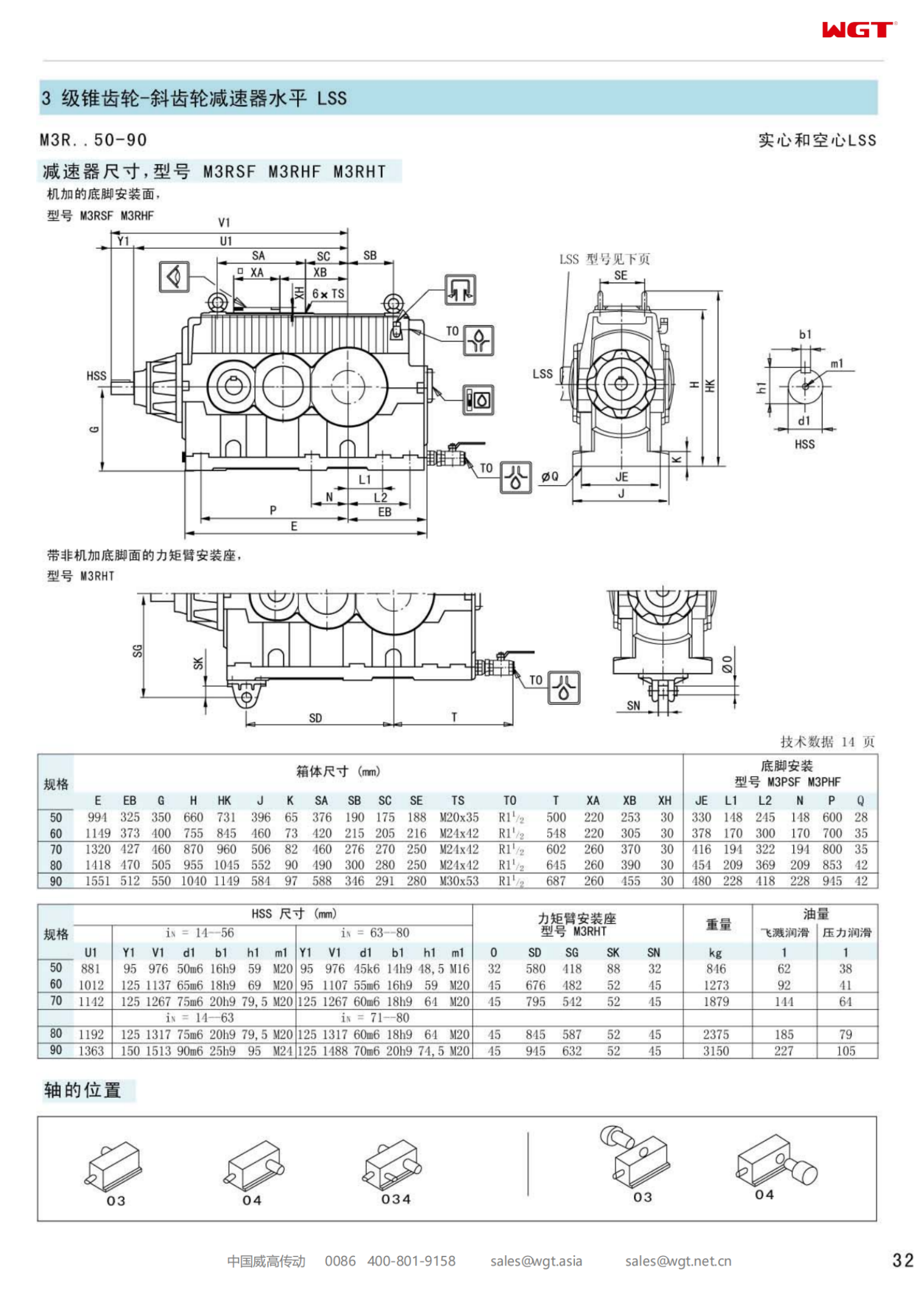

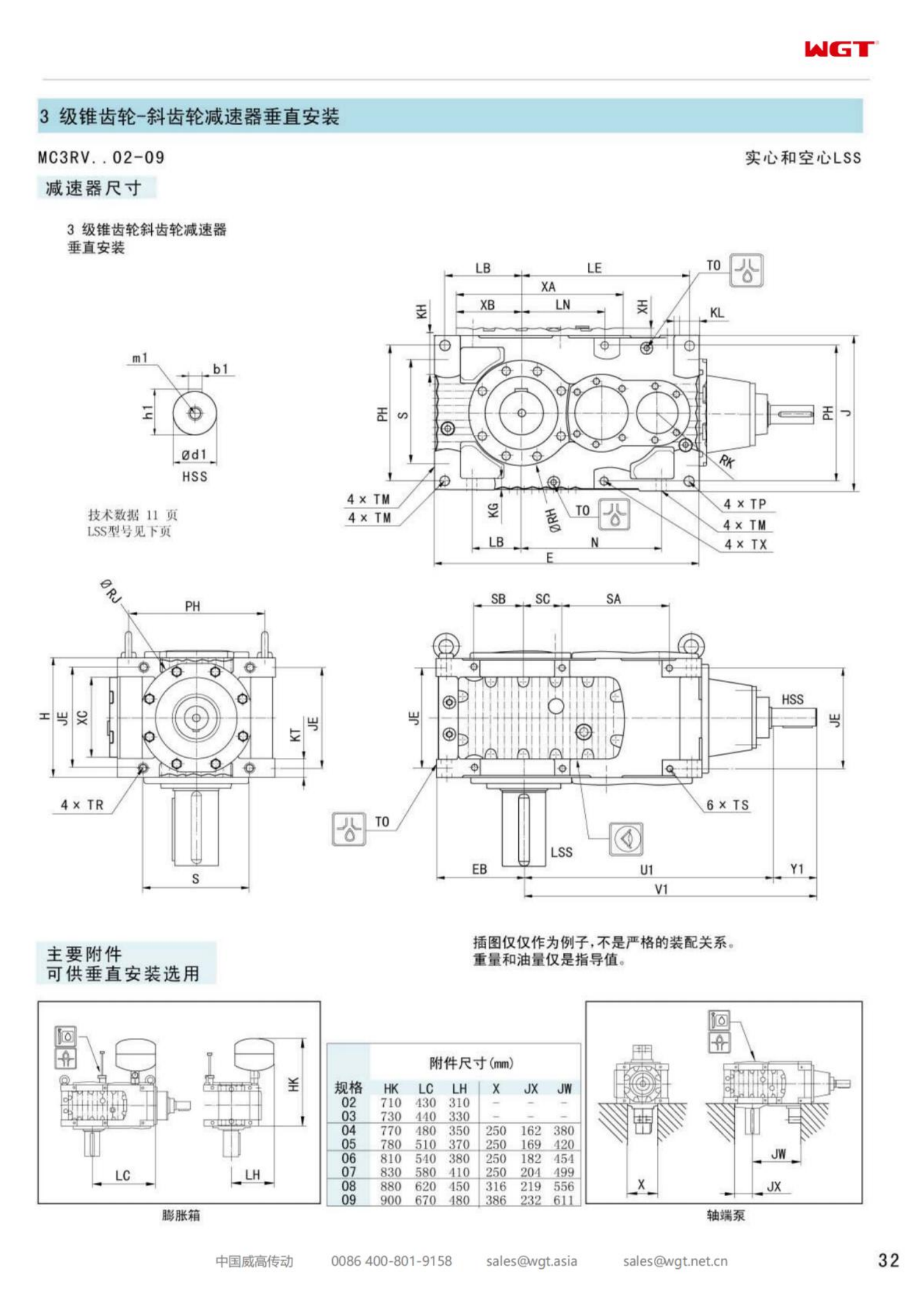

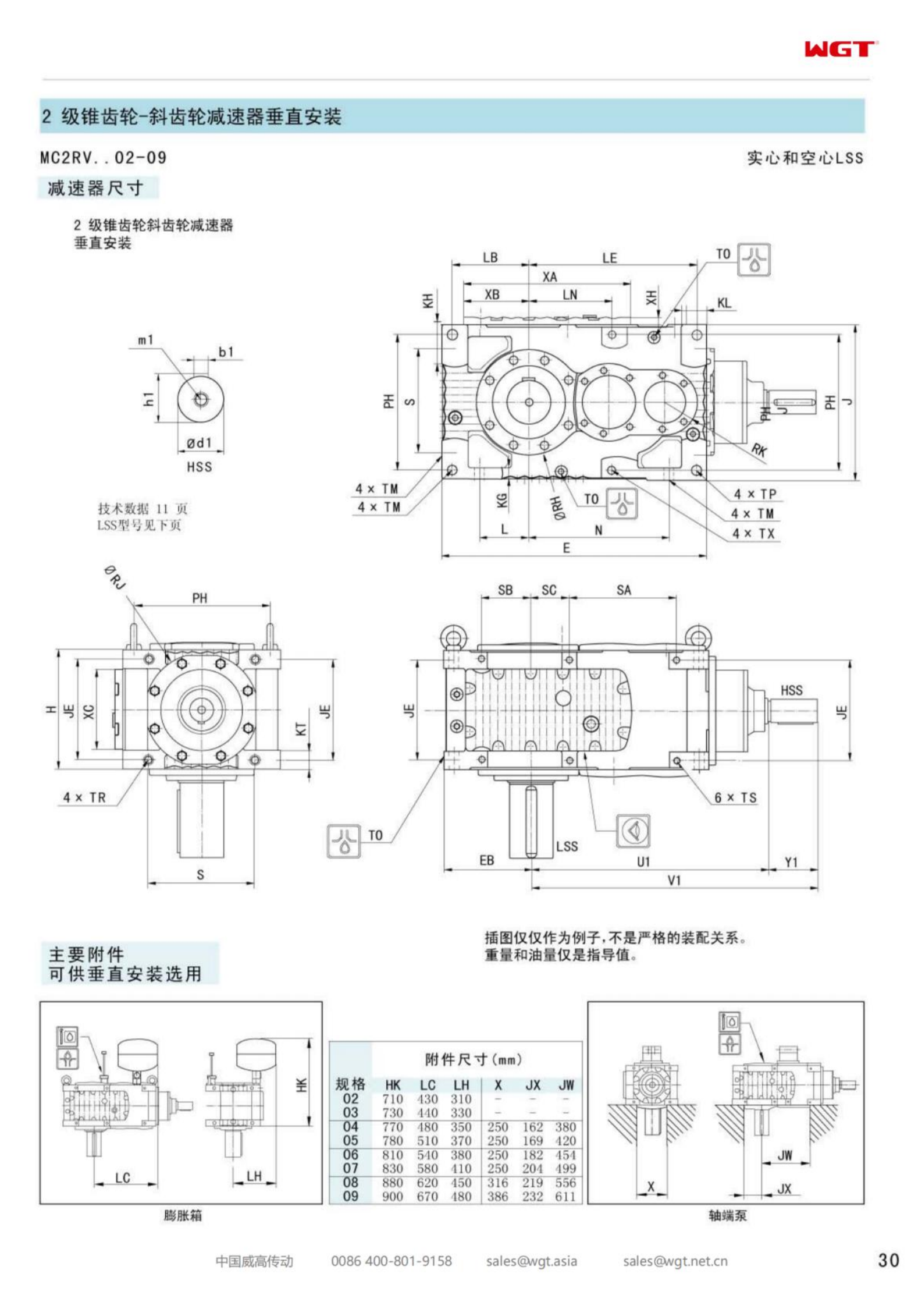

DCY three-stage transmission conical cylindrical gear reducer

The conical cylindrical gear reducer (hereinafter referred to as the reducer) is used for transmission devices in which the input shaft and the output shaft are arranged in a vertical direction. Mainly used in belt conveyors and various transportation machinery, but also in the transmission mechanism of various general machinery such as coal, metallurgy, mining, chemical industry, building materials, light industry, petroleum and so on.

DCY160, DCY180, DCY200, DCY224, DCY350, DCY280, DCY315, DCY355, DCY400, DCY450, DCY500, DCY560, DCY630, DCY710, DCY800

Speed ratios are 16, 18, 20, 22.4, 25, 28, 31.5, 35.5, 40, 45, 50

1. The use, performance characteristics and model marking of the reducer

1.1 Purpose

The conical cylindrical gear reducer (hereinafter referred to as the reducer) is used for transmission devices in which the input shaft and the output shaft are arranged in a vertical direction. Mainly used in belt conveyors and various transportation machinery, but also in the transmission mechanism of various general machinery such as coal, metallurgy, mining, chemical industry, building materials, light industry, petroleum and so on.

1.2 Performance characteristics

High carrying capacity, low noise, small size, light weight, high efficiency and long service life.

1.3 Parameter range

DBY, DBYK, and DBZ reducers each have 12 specifications, and the nominal center distance is: 160, 180, 200, 224, 250, 280, 315, 355, 400, 450, 500, 560mm. Each specification has 5 transmissions. Compared with (8, 10, 11.2, 12.5, 14) two rotation directions, four assembly types, respectively, make up 240 kinds of reducers.

There are 15 specifications for DCY, DCYK, and DCZ reducers. The nominal center distance is: 160, 180, 200, 224, 250, 280, 315, 355, 400, 450, 500, 560, 630, 710, 800mm; each Each specification has 11 transmission ratios (16, 18, 20, 22.4, 25, 28, 31.5, 35.5, 40, 45, 50), two rotation directions, four assembly types, and 660 types of reducers.

This series of reducers can meet the power requirements of TD and DX belt conveyors and other transportation machinery in the working range of 0.8-6.5m/s belt speed.

1.4 Structure

Lubrication of reducer: Under normal circumstances, gears and bearings of reducer are lubricated by splashing oil pool and cooled naturally. Only when the working equilibrium temperature of the reducer exceeds the specified value, or the carrying power exceeds the thermal power PG1, the oil pool with cooling pipe is used for lubrication.

1.5 Model and marking

The model of the reducer is composed of type code, nominal center distance a (center distance of the final stage), nominal transmission ratio, assembly type code, and input shaft rotation direction code.

D-belt conveyor group code, B-two-stage transmission, C-three-stage transmission, Y-hardened gear, Z-medium hardened gear, K-output shaft is a hollow shaft.

Nominal center distance: expressed by actual numbers, the unit is mm

Transmission ratio: expressed by the nominal transmission ratio.

Assembly type: indicated by Roman numerals I, II, III, IV.

The direction of rotation of the input shaft: When looking at the direction of the input shaft, S is clockwise and N is counterclockwise.

Markup example:

The nominal center distance is 280mm, the nominal transmission ratio is 31.5, the assembly type is Type III, and the input shaft is clockwise rotating. The mark of the three-stage transmission reducer is: reducer DCY280-31.5-III S