Online paper book

Online paper book  PDF Product Catalog

PDF Product Catalog

Product introduction:

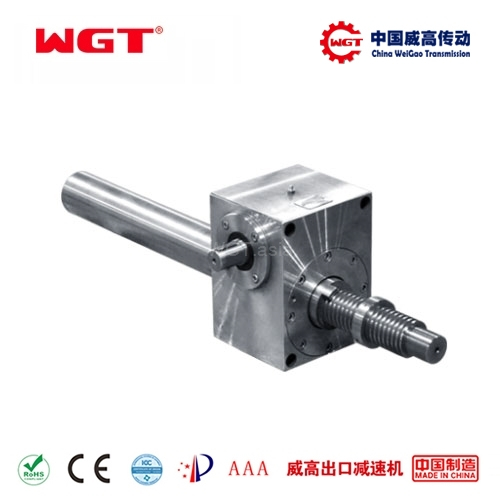

The SWL series worm gear worm lift is the basic lifting component, which completes the lifting, lowering, advancing and turning functions through the worm gear driving screw. It has been listed as JB / T8809-1998 standard. It is widely used in machinery, metallurgy, water conservancy, chemical industry, medical treatment, culture, sanitation and other industries. Compact structure, small size, light weight, easy installation, flexible and reliable use. Strong performance, long service life and other advantages, can be directly driven by electric motor or other power, can also be manually operated. This series of worm gears and screws can be self-locking, and the load-bearing capacity is 2.5T ~ 120T.

Product introduction and function:

The SWL series worm gear worm lift is the basic lifting component, which completes the lifting, lowering, advancing and turning functions through the worm gear driving screw. It has been listed as JB / T8809-1998 standard. It is widely used in machinery, metallurgy, water conservancy, chemical industry, medical treatment, culture, sanitation and other industries. Compact structure, small size, light weight, easy installation, flexible and reliable use. Strong performance, long service life and other advantages, can be directly driven by electric motor or other power, can also be manually operated. This series of worm gears and screws can be self-locking, and the load-bearing capacity is 2.5T ~ 120T. The maximum input speed is 1500 r / min, and the maximum lifting speed is 2.7 m / min. There are different structures and components. The working environment temperature is between -20 and 100 degrees Celsius, and the lifting height is manufactured according to user requirements.

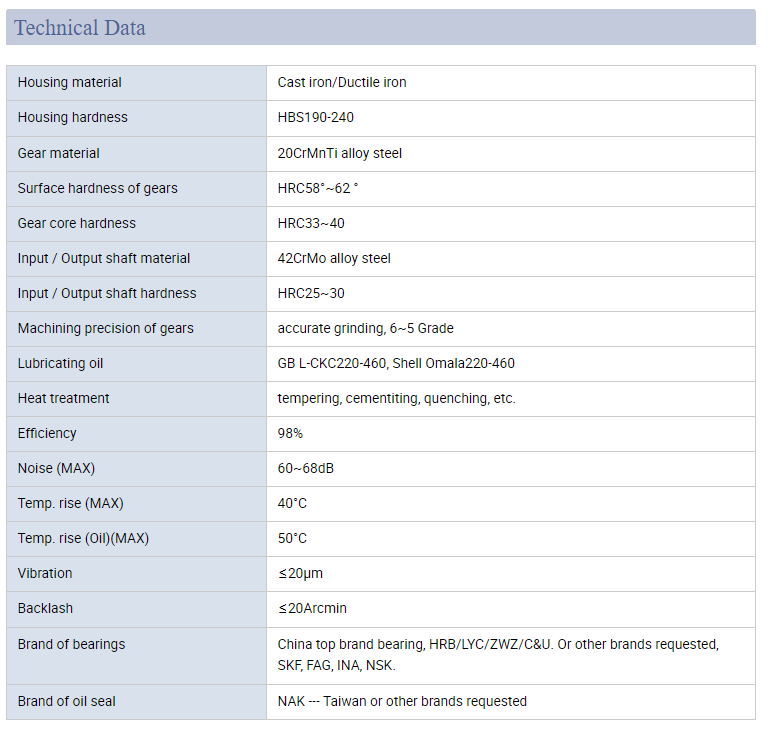

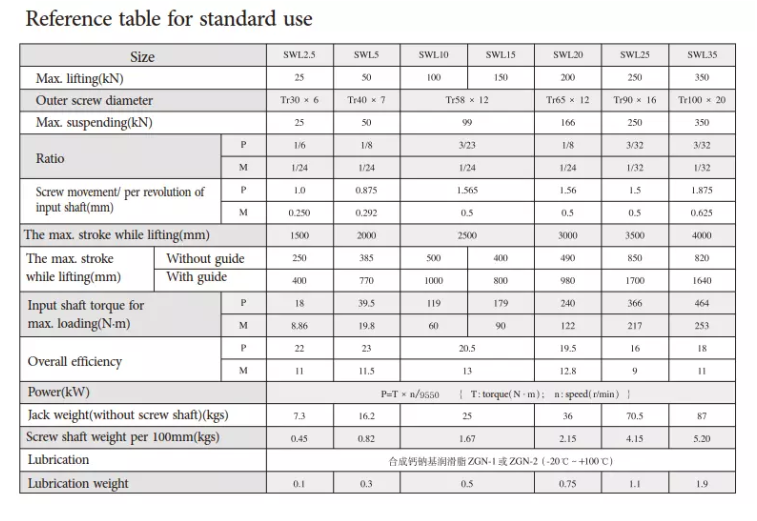

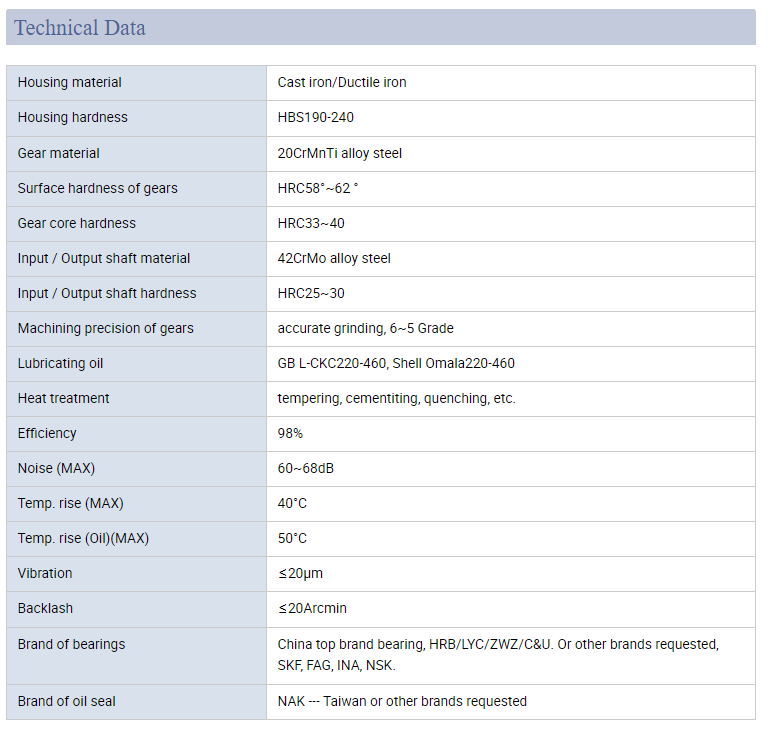

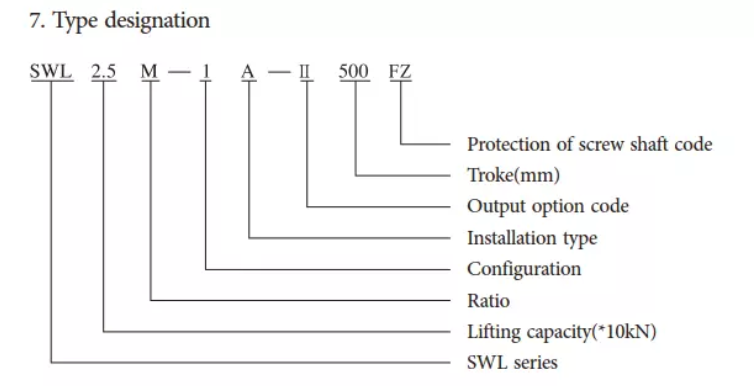

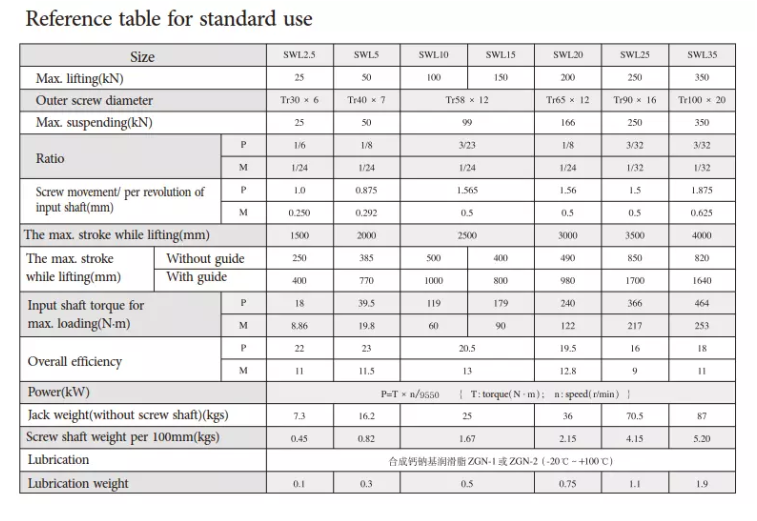

product data:

Lifting power: 25-1200KN

Screw outer diameter: 30 ~ 120 mm

Movement form: screw movement and nut movement

Input form: single-axis input, dual-axis input, flange input, flange + shaft input

Connector type: external thread, spherical hinge, pin hole end, flange end, pin hole

Scope of application:

1. Execution device for lifting, shifting, tightening and turnover of production line;

2. Equipment for fastening, lifting and turning in metallurgical equipment;

3. Lifting machinery, flexible tools and welding lifts used in automobile manufacturing, etc.

4. Lifting device of monocrystalline silicon and polycrystalline silicon grouting furnace in photovoltaic industry and tracking device of solar power generation;

5. Aerospace, defense, military, astronomical telescopes and other remote control execution devices;

6. Lifting device of lifting platform;

7. Shipbuilding, water conservancy, papermaking, food and warehousing, casting and other industries; various implementation agencies of medical equipment, woodworking machinery and food machinery;

8. Lifting device on vertical and gantry machine tools.

Product advantages:

1. Generally good rigidity after power failure, accurate positioning and self-locking;

2. The system has a simple structure and a compact structure without complicated pumps, valves, fuel tanks or gas sources, and piping systems.

3. Low noise, no liquid leakage, almost no pollution to the environment, is an ideal green environmental protection product.

4. Due to the use of the reducer mechanism, the system part realizes a very small drive source to transmit a large torque;

5. Worm gear screw elevator has the characteristics of high mechanical precision, compact design, durability, less maintenance time and long service life. In addition, in the absence of other mechanical devices, you can rely on clutches, shafts, motors and relatively simple driving schemes to achieve some linear or rotary motion.

6. A closed-loop servo control system can be constructed to realize automatic control.

7. The use of standard originals, simple assembly, save time and effort.

8. The installation is simpler and the running time can be longer, because the heat dissipation efficiency is higher, thus prolonging the lubrication cycle.

If you need to customize the transmission scheme, product-specific parameters and shape and size, please contact the sales engineer.

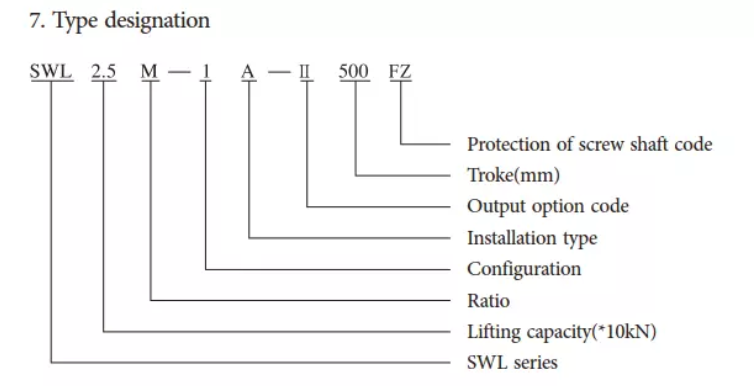

SWL series worm wheel screw elevator has the following models:

SWL2.5 SWL5 SWL10 SWL15 SWL20 SWL25 SWL35

JW series worm wheel screw elevator has the following models:

JWM010 JWM025 JWM050 JWM100 JWM150 JWM200 JWM300 JWM500 JWM750 JWM1000

JWB010 JWB025 JWB050 JWB100 JWB150 JWB200 JWB300 JWB500

Online paper book

Online paper book PDF Product Catalog

PDF Product Catalog