WP series reducer, the worm is made of 45# high-quality steel, after heat treatment, the worm wheel is made of tin bronze, which has good wear resistance, especially the bearing capacity is more obvious, mainly suitable for plastics, metallurgy, beverages, mines, hoist transportation, chemical construction and other machinery Equipment deceleration drive.

electronic content

electronic content  PDF catalog

PDF catalog

A. Features:

1. Stable transmission, low vibration, low impact, low noise, large reduction rate, strong air permeability, suitable for various mechanical equipment.

2. Single-stage transmission, large transmission ratio and compact structure.Most reducers have good self-locking performance, and the braking device can save mechanical equipment through braking requirements.

3. The friction loss between the worm wheel and the tooth surface of the worm wheel is large, the transmission efficiency is lower than that of the gear, it is easy to heat, and the temperature is high.

4. Lubrication and cooling requirements are higher.

5. Very good game.Worms and worms are manufactured according to national standards.

B. Working conditions:

1. The speed of the worm reducer should not exceed 1500r/min.

2. The working environment temperature is -40°C to +40°C.When the working environment temperature is below 0°C, the lubricant must be heated to 0°C before heating.When the working environment temperature is higher than 40°C, cooling measures must be taken.

3. The feed shaft of the worm gear reducer can rotate forward or reverse.

C. Note:

Worm gear shafts should not be used as input shafts.

2. When it leaves the factory, the machine cannot pump oil.Before operation, enough mechanical oil must be added.

3. The supporting motor (i.e. power supply) must not exceed the value specified in the symbol.

4. If the user wants to change the direction of the incoming shaft, please remove the lower end cover of the shaft, take out the worm and adjust 180. Load it.Depending on the mount without knocking, you can drive the two shafts slowly to engage them.

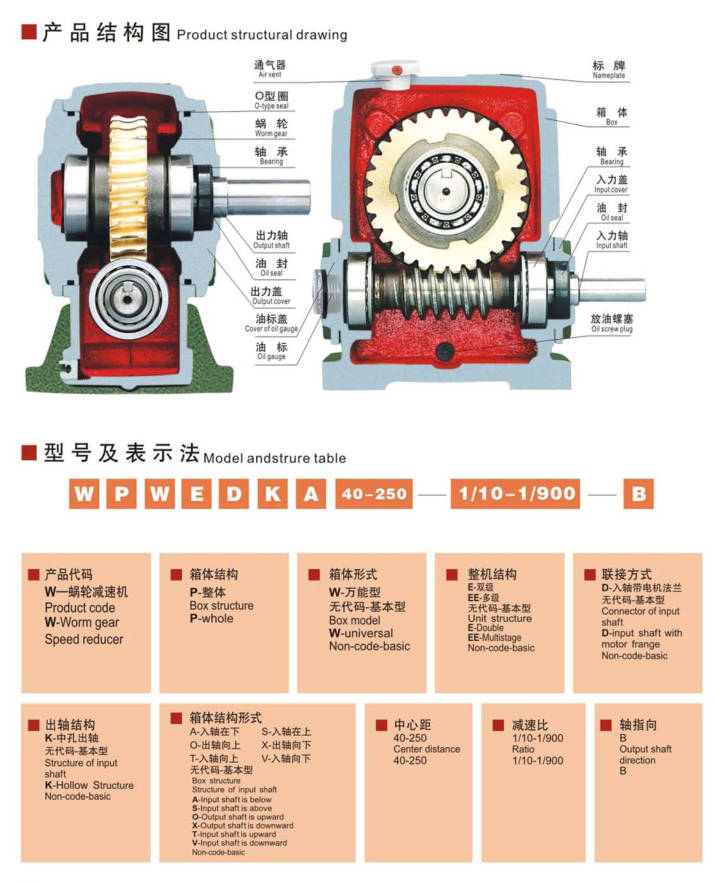

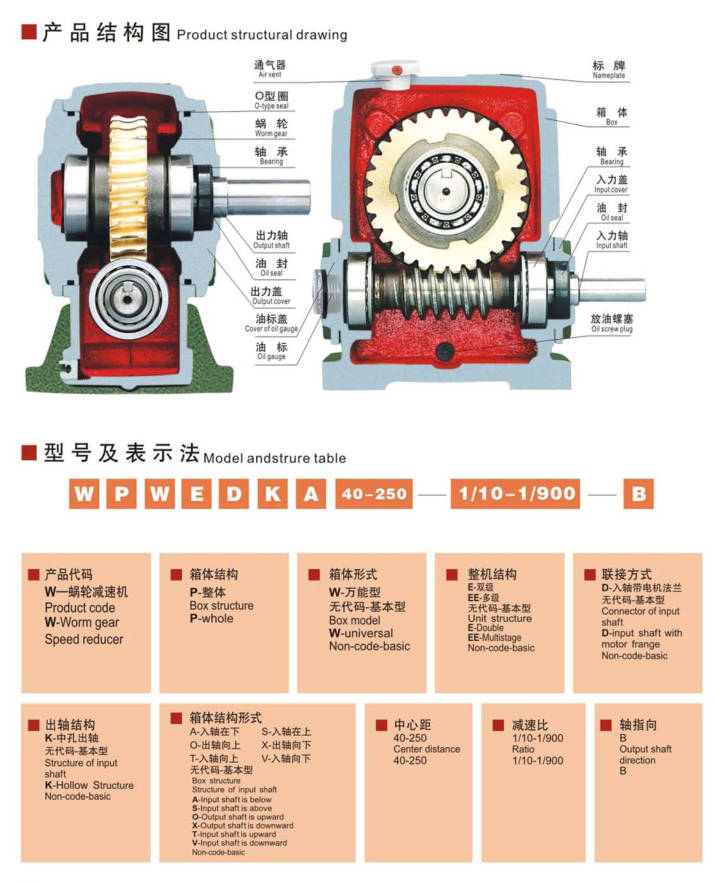

| Technical data |

| type: | WP Gearbox. |

| Specification: | WP 40-250 |

| Speed ratio: | 1: 10, 15, 20, 25, 30, 40, 50, 60, 200, 300, 400, 500, 600, 800, 900, 1200, 100, 1800, 2400, 2500, 3000, 3600 |

| color: | blue/silver or according to customer requirements |

Material: | Housing: cast iron casting Worm Gear - Copper-10-3# Carburized and Quenched Worm - 20crmn ti with a surface strand strength of 56-62HRC Shaft chrome steel 45# |

| pack: | Carton and Wooden Box |

| Bearing: | C&U bearer |

| seal: | NAK SKF. |

| ensure: | one year |

| input power. | 0.06kw, 0.09kw, 1.1kw, 1 5kw 2.2kw, 3kw, 4kw, 5 5kw, 7 5kw |

| use: | Industrial machinery: food, ceramics, chemical packaging, dyeing, woodworking, glass. |

| IEC flange: | 56b14, 63b14, 63b5, 63b5, 71b14, 80b14, etc. |

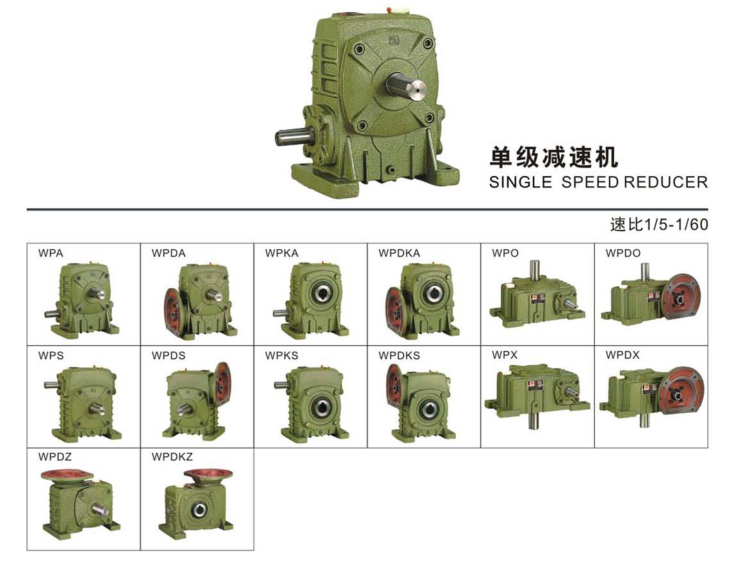

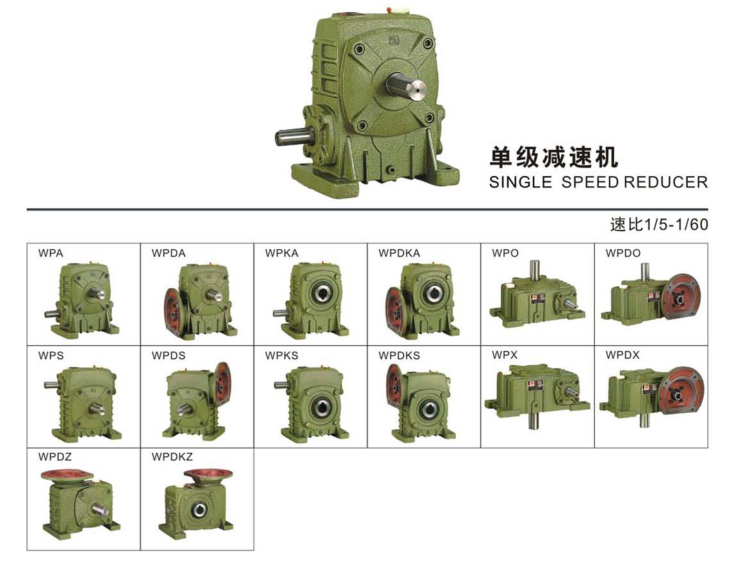

WPE double reducer ratio has the following models:

WPEA40-70 WPEA50-80 WPEA60-100 WPEA70-120 WPEA80-135 WPEA10-155 WPEA120-175 WPEA135-200 WPEA135-200 WPEA135-250

WPEDA40-70 WPEDA50-80 WPEDA60-100 WPEDA70-120 WPEDA80-135 WPEDA12-155 WPEDA120-175 WPEDA135-200 WPEDA155-250

WPEKA40-70 WPEKA50-80 WPEKA60-100 WPEKA70-120 WPEKA100-155 WPEKA120-175 WPEKA135-200 WPEKA155-250

WPEDKA40-70 WPEDKA60-80 WPEDKA70-120 WPEDKA80-135 WPEDKA100-155 WPEDKA120-175 WPEDKA135-200 WPEDKA155-250

WPEO40-70 WPEO50-80 WPEO60-100 WPEO70-120 WPEO80-135 WPEO100-155 WPEO120-175 WPEO135-200 WPEO155-250

WPEDO40-70 WPEDO50-80 WPEDO60-100 WPEDO70-120 WPEDO80-135 WPEDO10-155 WPEDO120-175 WPEDO135-200 WPEDO135-200 WPEDO155-250

WPES40-70 WPES50-80 WPES60-100 WPES70-120 WPES80-135 WPES120-175 WPES120-175 WPES135-200 WPES155-250

WPEDS40-70 WPEDS50-80 WPEDS60-100 WPEDS70-120 WPEDS80-135 WPEDS80-147 WPEDS100-155 WPEDS120-175 WPEDS135-200 Weds125-200 Weds155-250

WPEKS40-70 WPEKS50-80 WPEKS70-100 WPEKS70-120 WPEKS10-155 WPEKS120-175 WPEKS135-200 WPEKS155-250

wpedks40-70 wpedks50-80 wpedks60-100 wpedks70-120 wpedks80-135 wpedks100-155 wpedks120-175 wpedks135-200 wpedks155-250

WPEX40-70 WPEX60-80 WPEX60-100 WPEX80-135 WPEX80-147 WPEX120-175 WPEX135-200 WPEX155-250 WPEX155-250

WPEDX40-70 WPEDX50-80 WPEDX70-100 WPEDX80-135 WPEDX10-147 WPEDX120-175 WPEDX135-200 WPEDX155-250

WPWE40-70 WPWE50-70 WPWE60-100 WPWE70-120 WPWE80-135 WPWE100-155 WPWE120-175 WPWE135-200 WPWE155-250

WPWED40-70 WPWED50-80 WPWED60-100 WPWED80-135 WPWED100-155 WPWED120-175 WPWED135-200 WPWED155-250

WPWEKO40-70 WPWEKO50-80 WPWEKO60-100 WPWEKO80-135 WPWEKO120-175 WPWEKO135-200 WPWEKO135-200 WPWEKO155-250

wpwedko40-70 wpwwedko50-80 wpwedko60-100 wpwedko70-120 wpwedko80-135 wpwedko100-155 wpwedko120-175 wpwedko135-200 wpwedko155-250

WPEEA40-70 WPEEA60-70 WPEEA60-100 WPEEA70-120 WPEEA80-135 WPEEA10-100-155 WPEEA120-175 WPEEA135-200 WPEEA135-200 WPEEA135-250

wpeedo40-70 wpeedo50-80 wpeedo60-100 wpeedo70-120 wpeedo80-135 wpeedo10-155 wpeedo120-175 wpeedo135-200 wpeedo135-200 wpeedo135-200 wpeedo155-250

WPWEK40-70 WPWEK50-80 WPWEK70-100 WPWEK80-135 WPWEK120-175 WPWEK135-200 WPWEK135-200 WPWEK135-200 WPWEK155-250

WPWEDK40-70 WPWEDK50-80 WPWEDK60-100 WPWDK70-120 WPWDK100-155 WPWEDK120-175 WPWEDK135-200 WPWDK155-250

as a tv cow

p For complete information on all models, specifications, speed ratios, prices, etc. of WP series products, please click here to view

electronic content

electronic content PDF catalog

PDF catalog