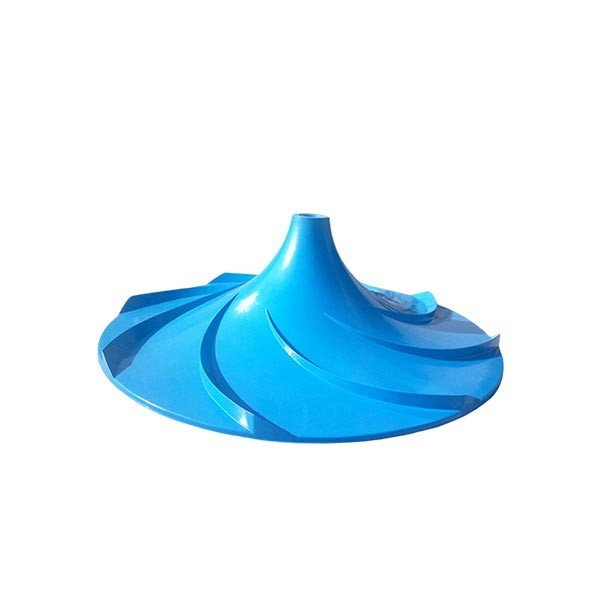

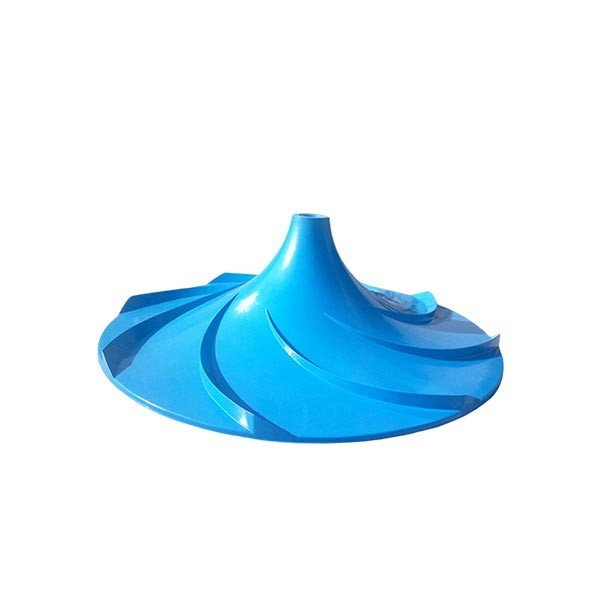

Introduction to hyperboloid mixer

This product has an aeration and stirring device with double-layer impellers. The upper surface of the hyperboloid impeller body is a hyperboloid structure formed by the rotation of the hyperbolic generatrix around the axis of the impeller body.Its unique impeller structure design maximizes the combination of fluid characteristics and mechanical movement.

1. It is a device that integrates stirring and aeration, and it can also be used for single stirring.

2. Reasonable design and low power consumption.

3. It can be applied to large, medium and small sewage treatment with less investment.

4. Good treatment effect and long service life.

5. It is made of PE or FRP, steel materials, etc., which strengthens the anti-corrosion performance of the equipment.

6. Simple structure and convenient management.

Application field

Municipal, chemical, environmental protection, papermaking and other fields.

Product Series

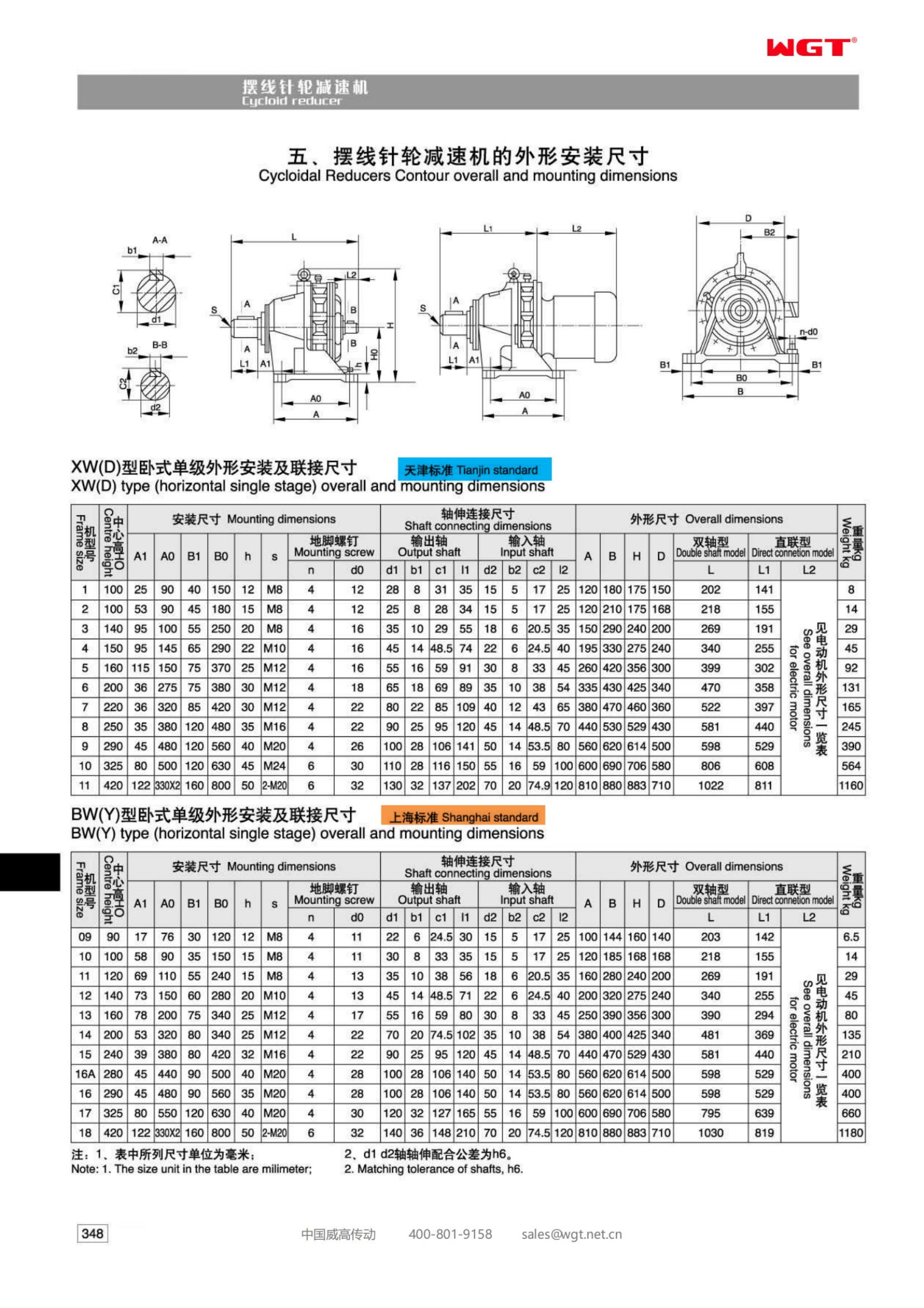

Cycloid mixer series

Power: 0.37kw, 0.55kw, 0.75kw, 1.1kw, 1.5kw, 2.2kw, 3kw, 4kw, 5.5kw, 7.5kw, 11kw, 15kw... (consult for details)

Specifications: 380v (three-phase), 220v (single-phase), anti-exposure motor, anti-static, etc.

Stirrer material: 304 stainless steel, 304 stainless steel lined with rubber, PO (lined with plastic), PP, PTFE, etc.

Stirrer and supporting form, size, specification, material: according to customer demand, stirring environment and motor power

Speed regulation mode: non-adjustable speed motor

Speed mode: fixed, the speed is selected according to the customer's mixing purpose

Color: optional according to customer needs

Weight: According to selected or customized models

Packing: wooden box

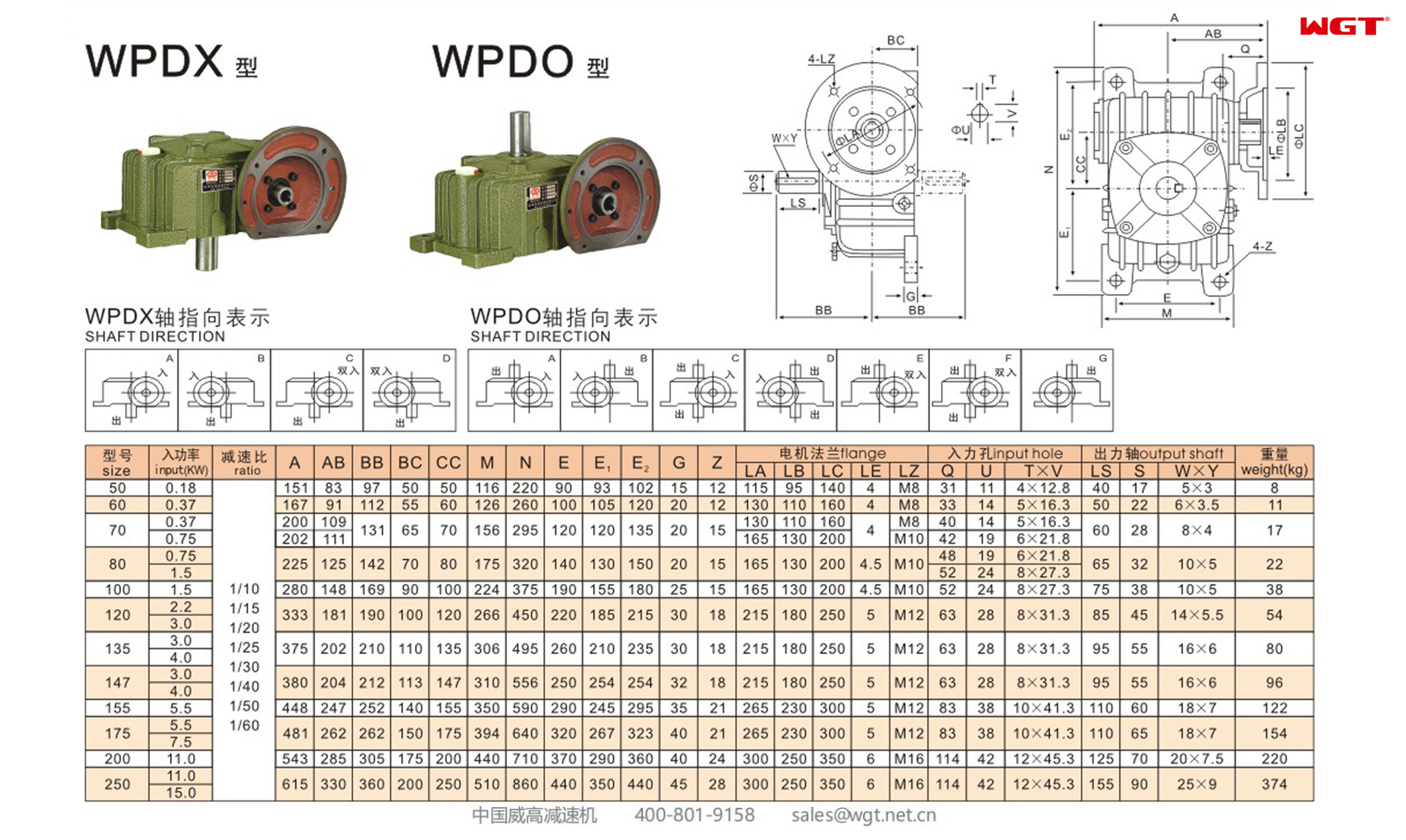

F series gear mixer

Model: F37~F157 (consult for details)

Power: 0.18kw~75kw

Specifications: 380v (three-phase), anti-exposure motor, anti-static, frequency conversion, etc.

Speed regulation mode: speed regulation, non-speed regulation motor

Speed mode: fixed, the speed is selected according to the customer's mixing purpose

Color: optional according to customer needs

Weight: According to selected or customized models

Packing: wooden box

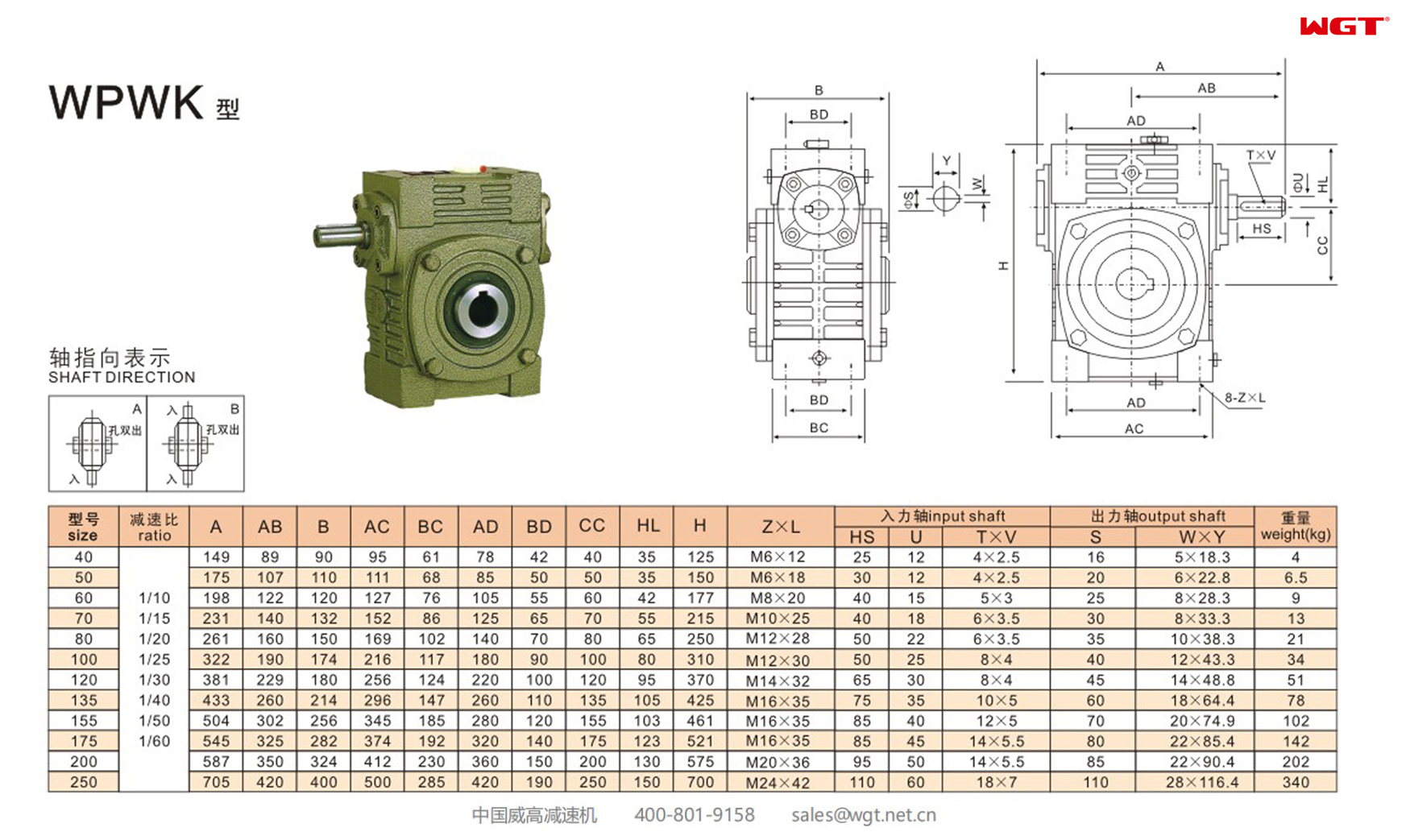

K series gear mixer

Model: K37~K187 (consult for details)

Power: 0.18kw~75kw

Specifications: 380v (three-phase), anti-exposure motor, anti-static, frequency conversion, etc.

Speed regulation mode: speed regulation, non-speed regulation motor

Speed mode: fixed, the speed is selected according to the customer's mixing purpose

Color: optional according to customer needs

Weight: According to selected or customized models

Packing: wooden box

R series gear mixer

Model: R17~R177 (consult for details)

Power: 0.18kw~75kw

Specifications: 380v (three-phase), anti-exposure motor, anti-static, frequency conversion, etc.

Speed regulation mode: speed regulation, non-speed regulation motor

Speed mode: fixed, the speed is selected according to the customer's mixing purpose

Color: optional according to customer needs

Weight: According to selected or customized models

Packing: wooden box

S series gear mixer

Model: S37~S100 (consult for details)

Power: 0.18kw~75kw

Specifications: 380v (three-phase), anti-exposure motor, anti-static, frequency conversion, etc.

Speed regulation mode: speed regulation, non-speed regulation motor

Speed mode: fixed, the speed is selected according to the customer's mixing purpose

Color: optional according to customer needs

Weight: According to selected or customized models

Packing: wooden box

Little King Kong Blender

Model: MYJG200-10 (consult for details)

Specifications: 380v (three-phase), 220v (single-phase), anti-exposure motor, anti-static, frequency conversion, etc.

Speed regulation mode: speed regulation, non-speed regulation motor

Speed mode: fixed, the speed is selected according to the customer's mixing purpose

Color: optional according to customer needs

Weight: According to selected or customized models

Packing: wooden box

Production advantages of mixer products

1. Large product coverage and wide application range

The products are diverse, satisfying the mixing scenes of solid & solid, liquid & liquid, solid & liquid, gas & liquid and other combinations.According to the various environments of customer applications, top, side and bottom installation methods are provided.According to the flow direction, there are hundreds of mature craft products such as propulsion type, turbine type, frame type, anchor type, spiral belt type, screw type, spiral belt + screw type, etc.The equipment process can reach agitator length of more than 12 meters, stirring diameter of more than 5 meters (call for details), agitator surface coating, spraying and body carbon steel, stainless steel, titanium and other materials can be selected.

2. Mature research and development, providing customers with a complete set of solutions

More than ten years of experience in technology research and development, a mature technical team, professional paddle Selection and corresponding simulation calculation of stirring speed, tailor-made solutions for customers.

3. Strict material selection standards, five material selection guarantees

The company has cooperated with well-known material suppliers for many years, and the selected raw materials (plates, round pipes, round bars, etc.) are all provided by large domestic steel manufacturers.Supporting the company's specific five-item material guarantee standard, it is stable and reliable.

4. Exquisite processing equipment and technology

The products are formed by high-tech laser cutting and blanking, automatic processing by CNC machine tools, and self-made finished products in the whole process of compression molding, welding and assembly.

5. Eight unique quality inspection standards

The company specially formulates and adheres to eight major production testing standards to ensure that every manufactured product meets the standards and customer needs, which greatly improves the rate of finished products.

6. Fast delivery

Based on mature R&D technology and scientific production process, the whole process is self-made, and each production and inspection link is systematically controlled.Better shorten the production cycle to meet customer needs.

7. Non-standard customization, rich experience

The company provides non-standard customized solutions for various scenarios and customer needs throughout the year, hundreds of product processes and combinations, and more than a thousand types of non-standard scenario customized solutions to meet customers' all-round product needs.