Brief introduction of BWD horizontal cycloid reducer

B series cycloidal pin gear reducer is a kind of machine that realizes deceleration by cycloidal pin gear meshing according to the principle of planetary transmission with small tooth difference.The machine is divided into horizontal, vertical, biaxial and direct-connected assembly methods.

1. Large reduction ratio and high efficiency.The reduction ratio of the first-stage transmission is 9~87, the reduction ratio of the two-stage transmission is 121~5133, the multi-stage combination can reach tens of thousands, and the pin-tooth meshing system is sleeve-type rolling friction, and the meshing surface has no relative sliding, so the efficiency of the first-stage reduction reaches 94%.

2. Stable operation and low noise.There are many pairs of teeth in contact with each other during operation, the degree of overlap is large, the operation is stable, the overload capacity is strong, the vibration and noise are low, and the models of various specifications have low noise.

3. Reliable use and long service life.Because the main parts are made of high-carbon alloy steel after quenching treatment (HRC58-62), and then finely ground, and the cycloid teeth mesh with the pin gear sleeve and transmit to the pin teeth to form a rolling friction pair. The friction coefficient is small, so that there is no relative friction in the meshing area. It slides with minimal wear, so it's durable.

4. Compact structure and small volume.Compared with other reducers of the same power, the weight and volume are more than 1/3 smaller. Due to the planetary transmission, the input shaft and output shaft are on the same axis to obtain the smallest possible size.

Application range

Widely used in petrochemical, metallurgy, mining, construction, chemical, textile, lifting transportation, light industry, food and other industries.

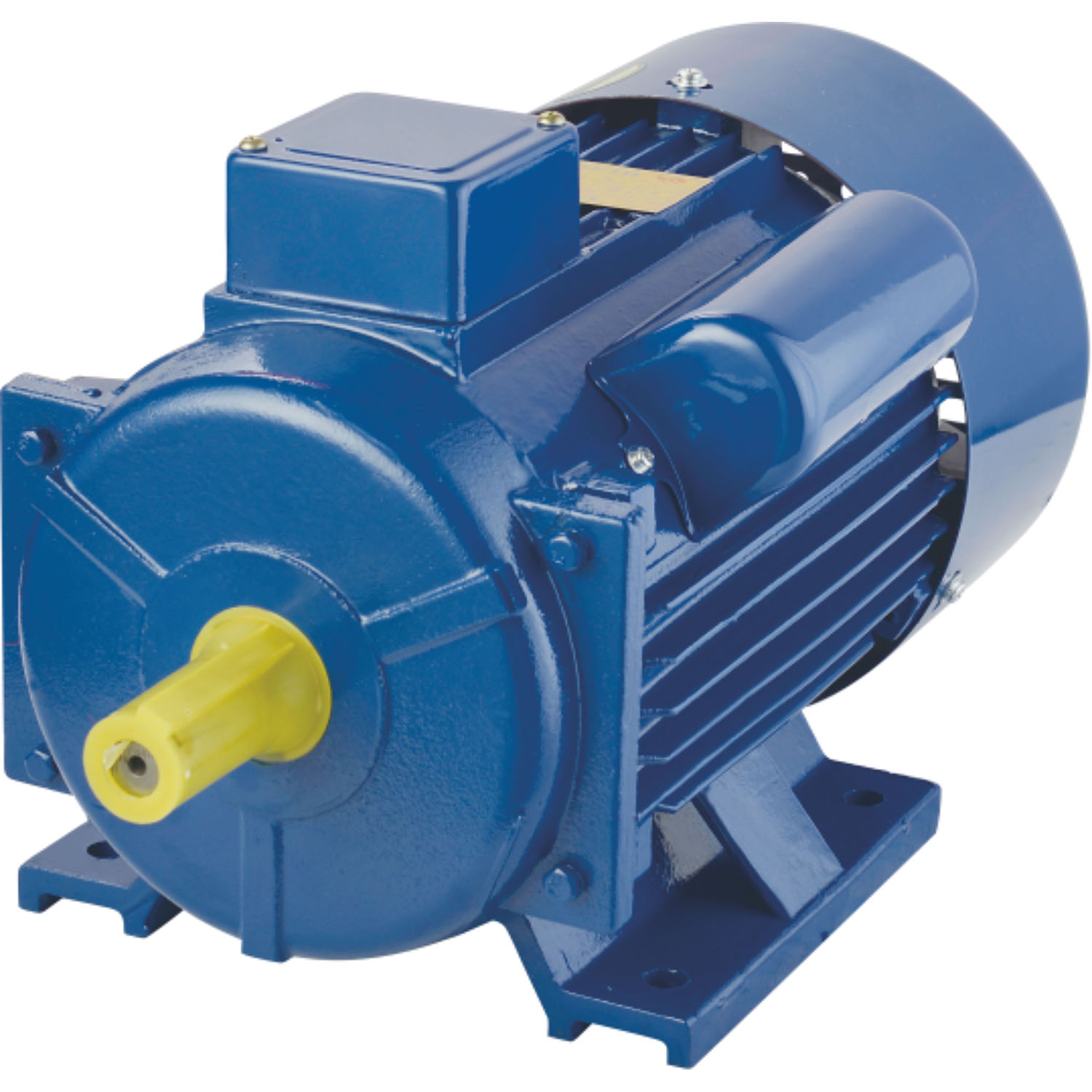

BWD horizontal cycloid reducer

Model: 0.37kw, 0.55kw, 0.75kw, 1.1kw, 1.5kw, 2.2kw, 3kw... (consult for details)

Power: 380v (three-phase), 220v (single-phase), anti-exposure motor, anti-static, frequency conversion, etc.

Speed regulation mode: speed regulation, non-speed regulation motor

Speed mode: fixed, the speed is selected according to the customer's mixing purpose

Color: optional according to customer needs

Weight: According to selected or customized models

Packing: wooden box

Product advantages

High speed ratio: The maximum speed ratio of the primary transmission is 87; the maximum speed ratio of the secondary transmission is 7569, and more transmission stages can be used as required

Compact structure and small size: The input shaft and the output shaft are on the same axis, so the structure is compact and the volume is small.

Easy disassembly and maintenance: Reasonable structural design, simple disassembly and assembly, and easy maintenance.

Smooth operation and low noise: The cycloidal needle has a large number of meshing teeth, a large overlapping coefficient, and a mechanism of stable parts, so that the vibration and noise are controlled to a small degree.

Reliable use and long life The main transmission meshing parts are made of bearing steel, which has good mechanical properties, smooth rolling friction, and is more durable and has a long service life.

Strong overload capacity, impact resistance, small moment of inertia The number of meshing teeth is more than 3 times that of conventional involute gears. It has strong overload resistance and adopts a unique arc tooth shape without broken teeth.

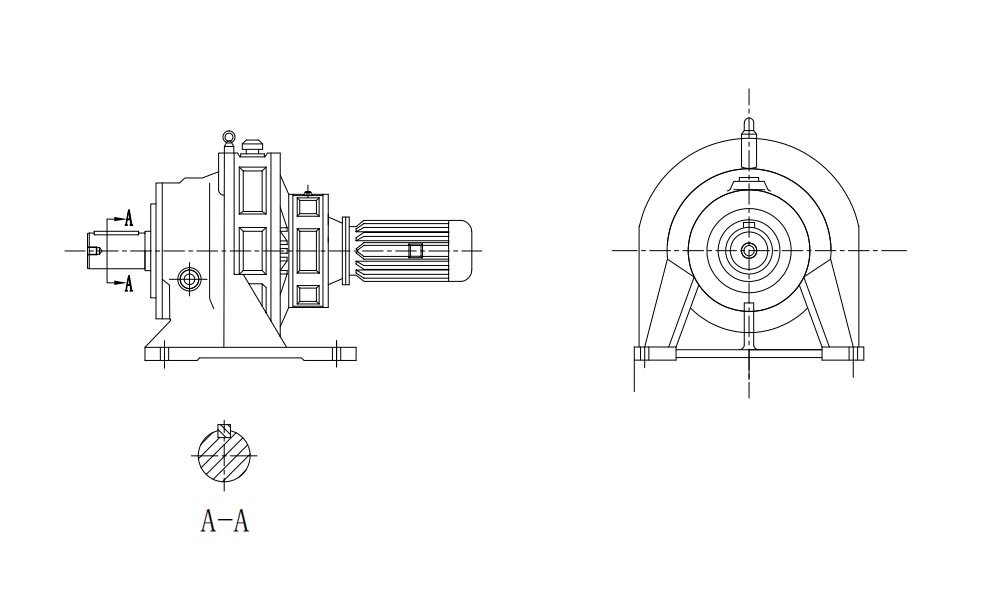

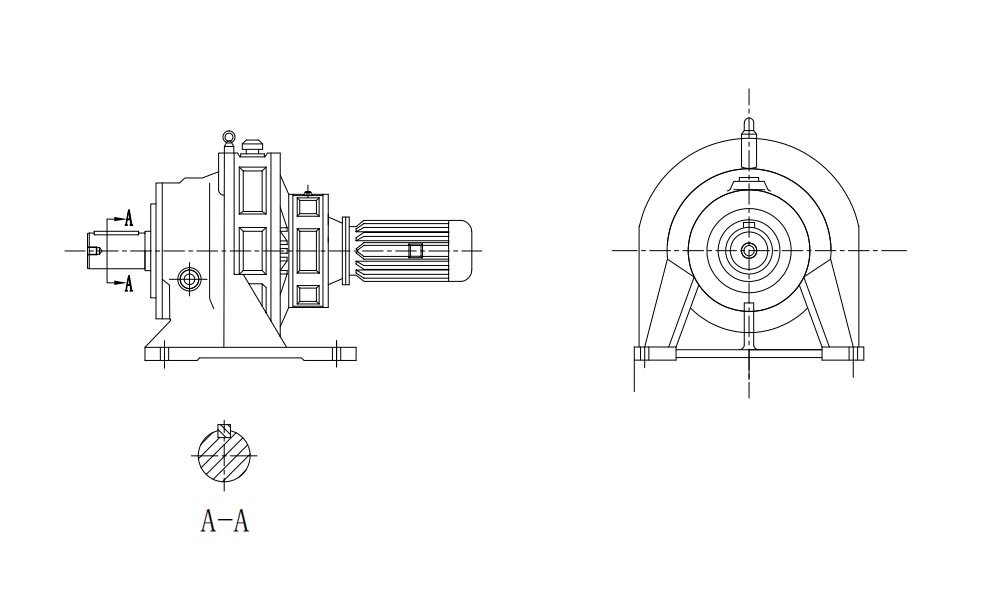

structure

Model and parameters

Machine model and transmission ratio

Machine model |

level one | Secondary | Level three |

09 | 10 | 2009 |

0 | 20 | 301 |

1 | 31 | 420 |

2 | 41 | 531 |

3 | 42 | 631 |

4 | 52 | 742 |

5 | 53 | 852 |

6 | 63 | 953 |

7 | 74 |

|

8 | 84 |

|

9 | 85 |

|

| 95 |

|

transmission ratio |

level one | Secondary | Level three |

7 | 99 (9×11) | 1505 (35×43) | See the parameter book for details |

9 | 121 (11×11) | 1849 (43×43) |

11 | 187 (11×17) | 2065 (35×59) |

17 | 289 (17×17) | 2537 (43×59) |

23 | 391 (17×23) | 3481 (59×59) |

29 | 493 (17×23) | 4189 (59×71) |

35 | 595 (17×35) | 5133 (59×87) |

43 | 731 (17×43) | 7569 (87×87) |

59 | 841 (29×29) |

|

71 | 1003 (17×59) |

|

87 | 1225 (35×35) |

|

Note:1. According to the structural form, it is divided into: horizontal type and vertical type; according to the drive connection mode, it is divided into: double-axis type, motor connection type, and motor direct connection type.

2. Where the transmission ratio of the first-stage model, the second-stage and third-stage models can be combined arbitrarily.

Model comparison table

Reducer standard | level one |

JB/T2982-94A | X1 | X2 | X3 | X4 | X5 | X6 | X7 | X8 | X9 | X10 | X11 | X12 |

JB/T2982-94B | B09 | B0 | B1 | B2 | B3 | B4 | B5 | B6 | B7 | B8 | B9 |

JB/2982-81 |

| B12 | B15 | B18 | B22 | B27 | B33 | B39 | B45 | B55 | B65 |

Reducer standard | Secondary |

JB/T2982-94A | X32 | X43 | X53 | X63 | X64 | X74 | X84 | X85 | X195 | X106 | X118 | X128 |

JB/T2982-94B | B10 | B20 | B31 | B41 | B42 | B52 | B53 | B63 | B74 | B85 | B95 |

JB/2982-81 |

| B1812 | B2215 | B2715 | B2718 | B3318 | B3322 | B3922 | B4537 | B5533 | B6533 |

Note:The corresponding machine models of different standards have basically the same performance indicators, but the appearance, installation and connection dimensions are slightly different.Users try to use JB/T2982-94A and B standards first.

Model representation method