- Home

- About Us

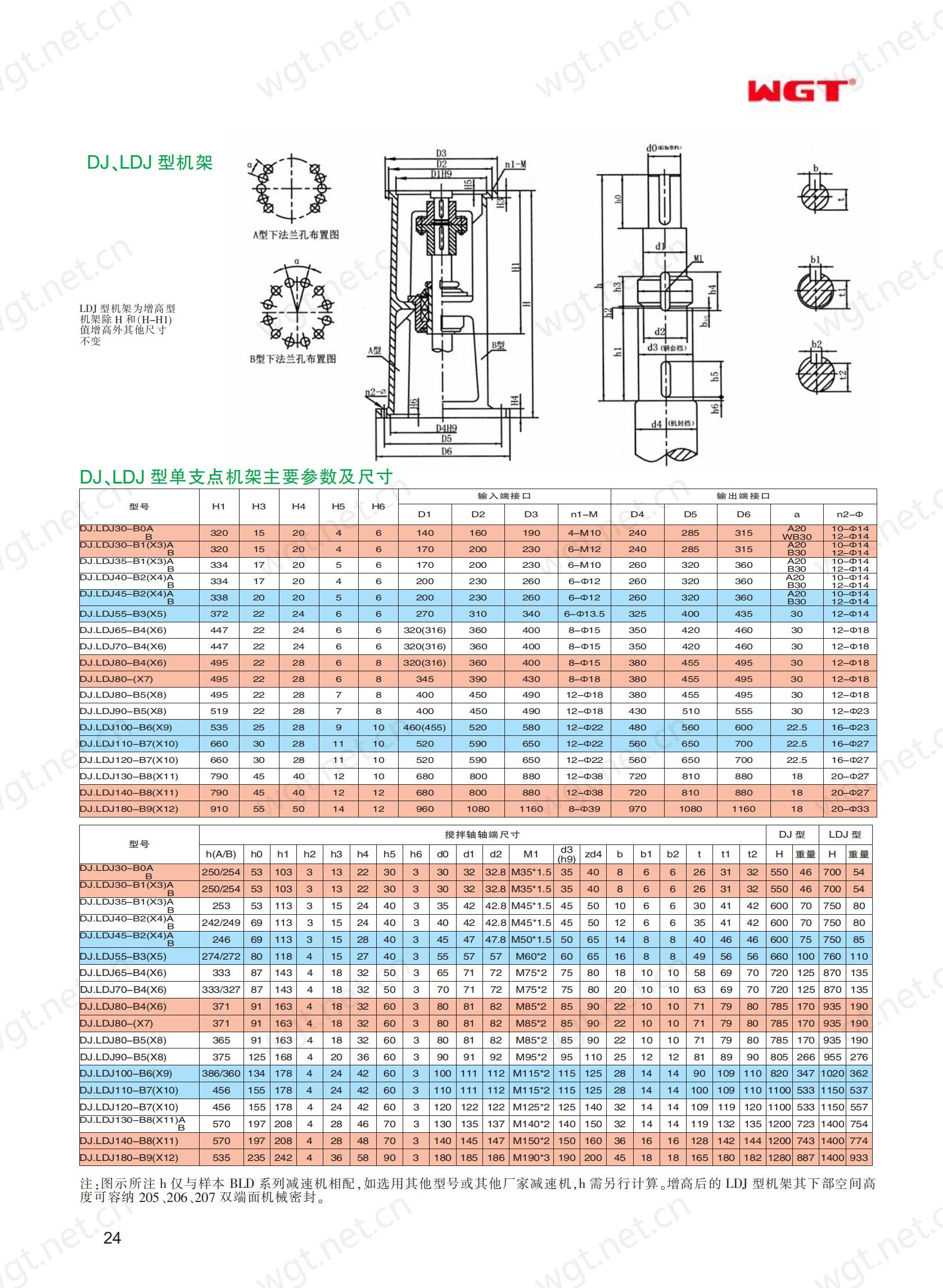

- Products

- R series helical gear reducer

- S series helical gear worm reducer

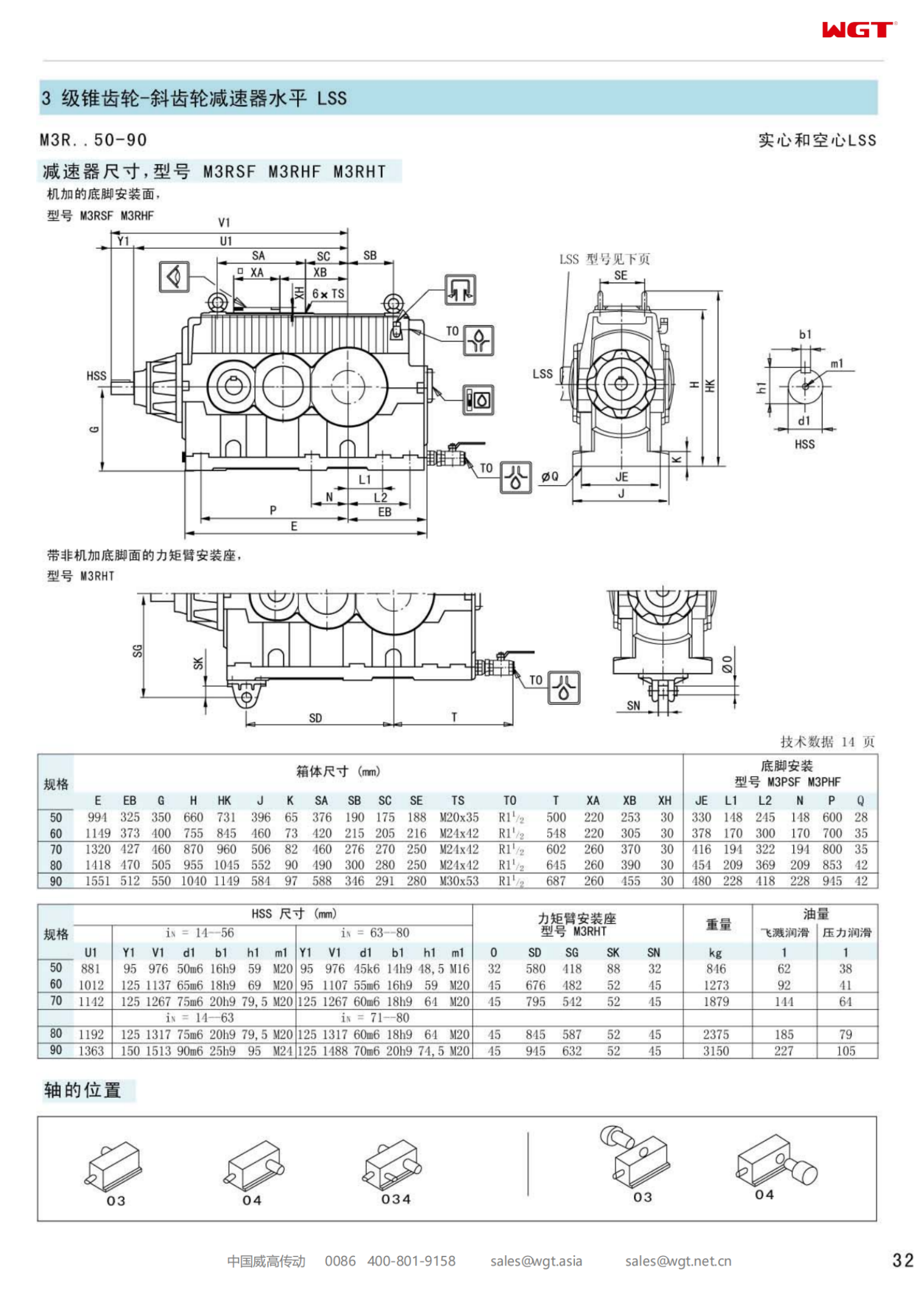

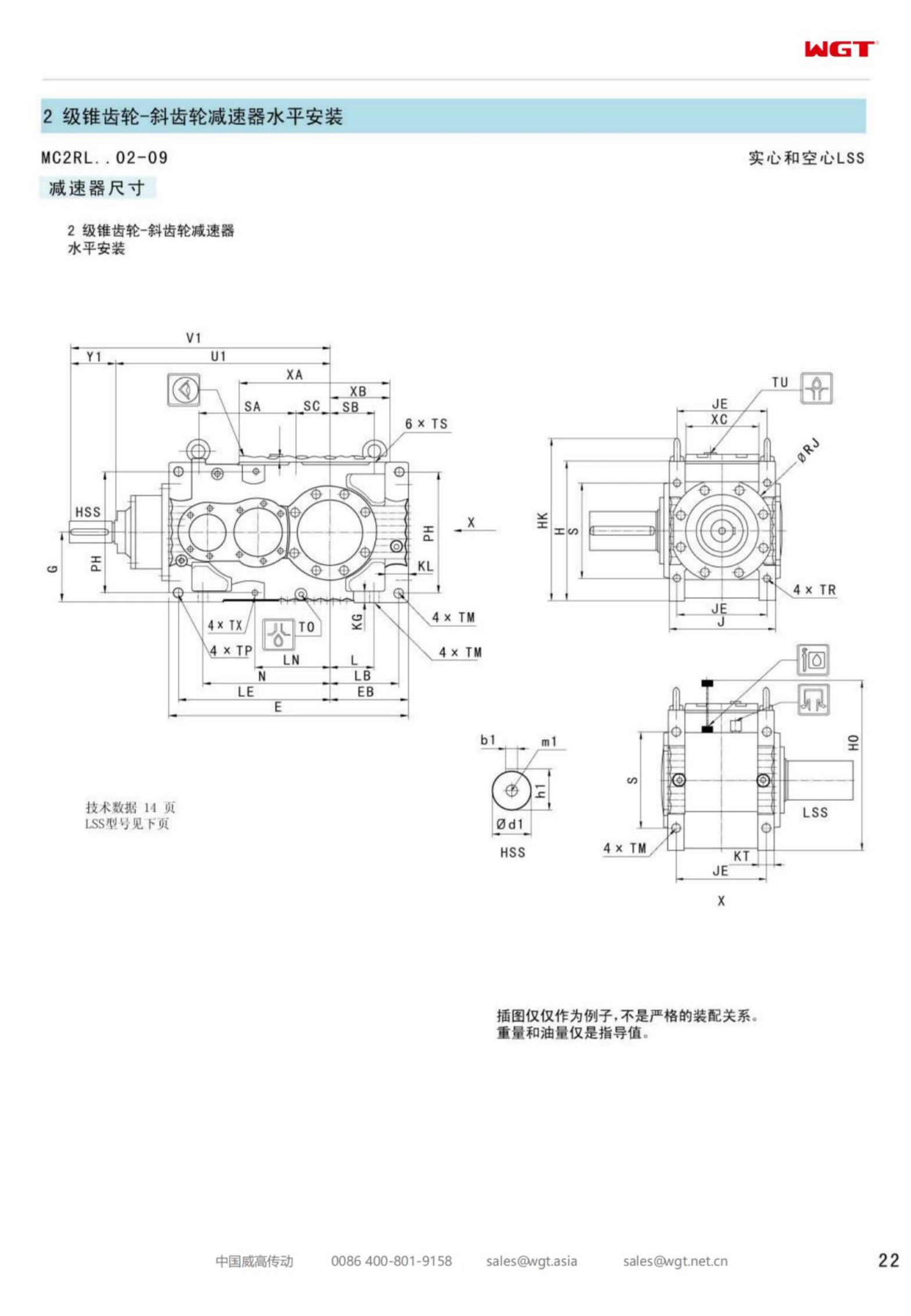

- K series helical bevel gear reducer

- F series parallel shaft helical gear reducer

- HB series industrial gearbox

- P series planetary gear reducer

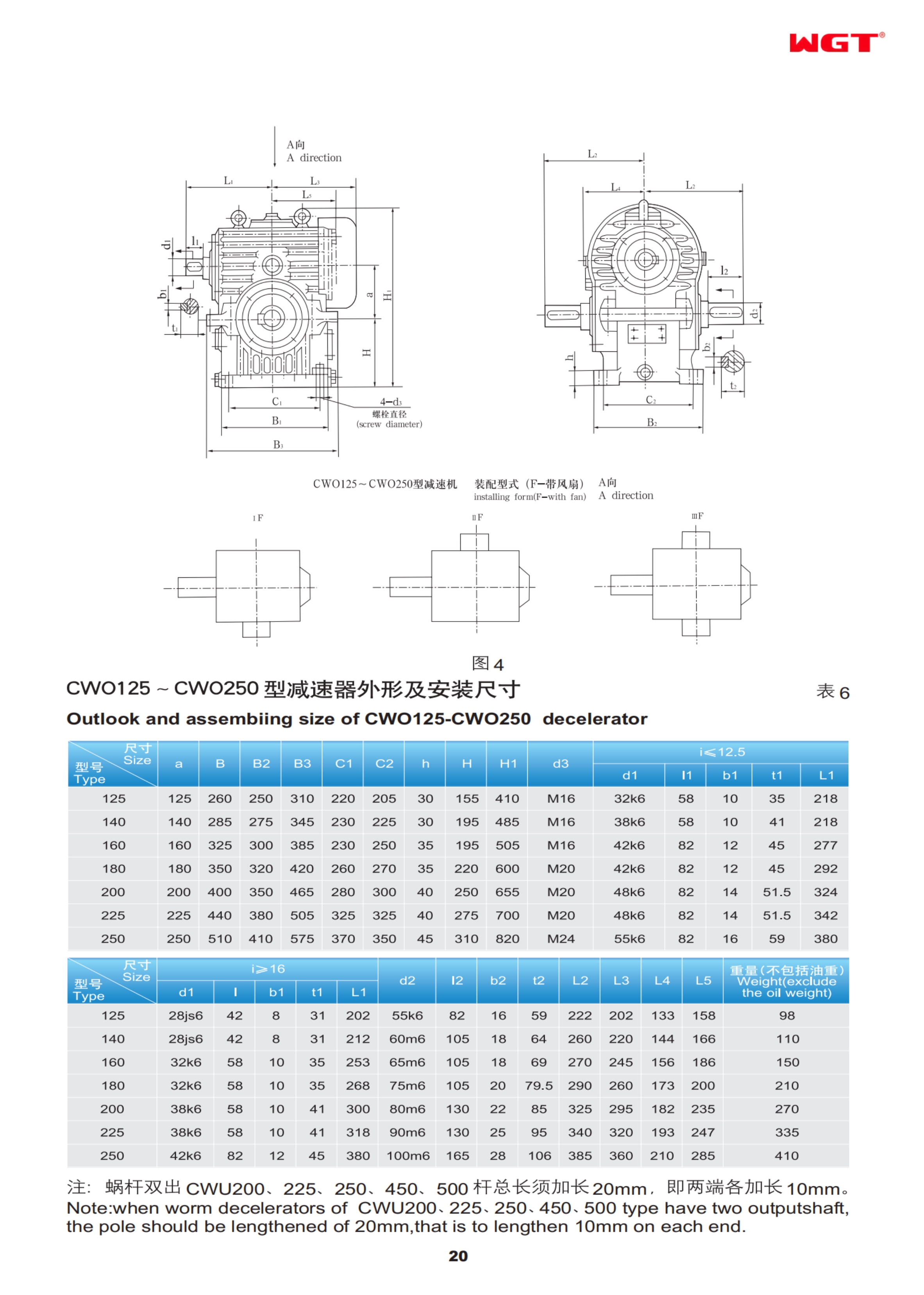

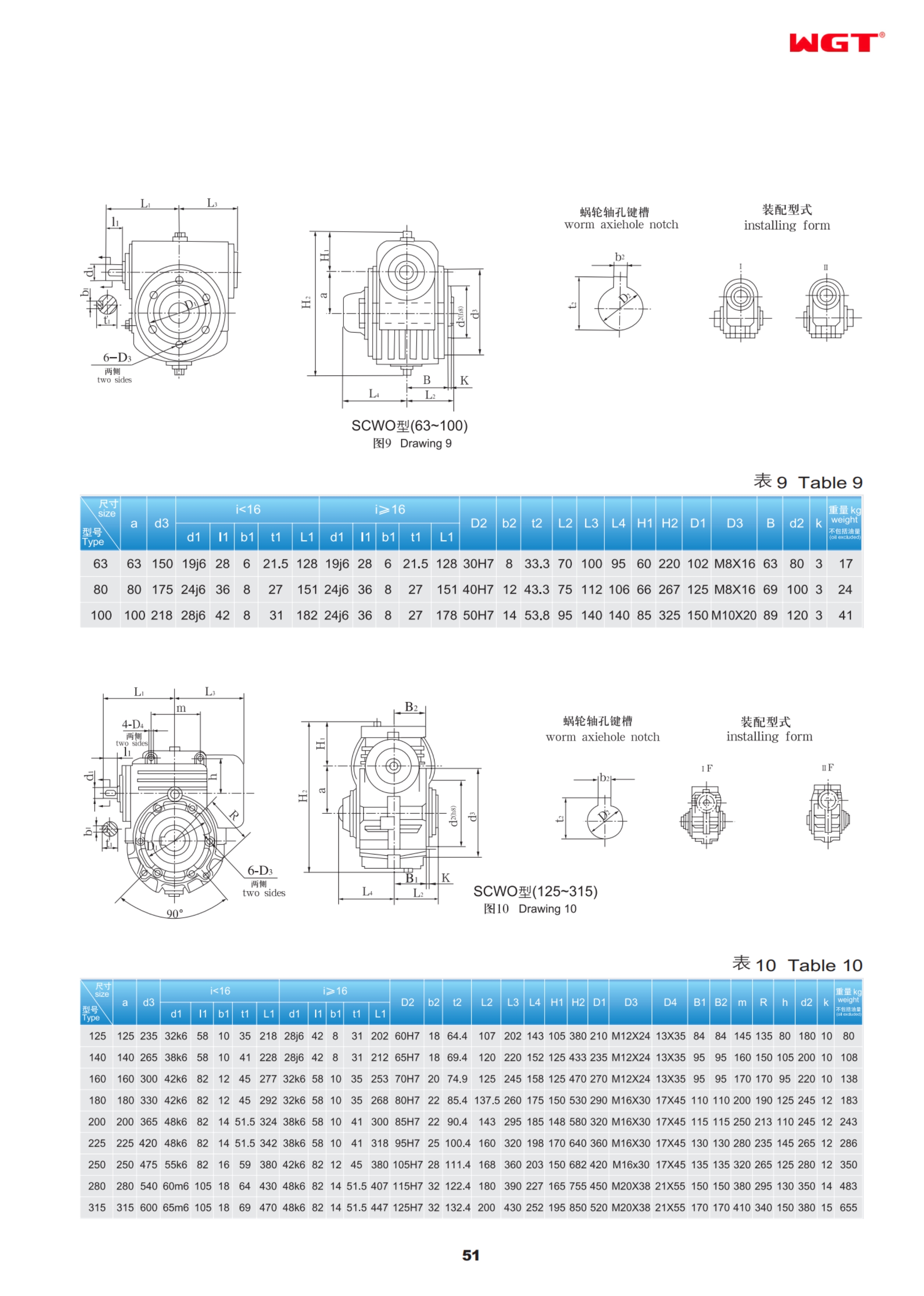

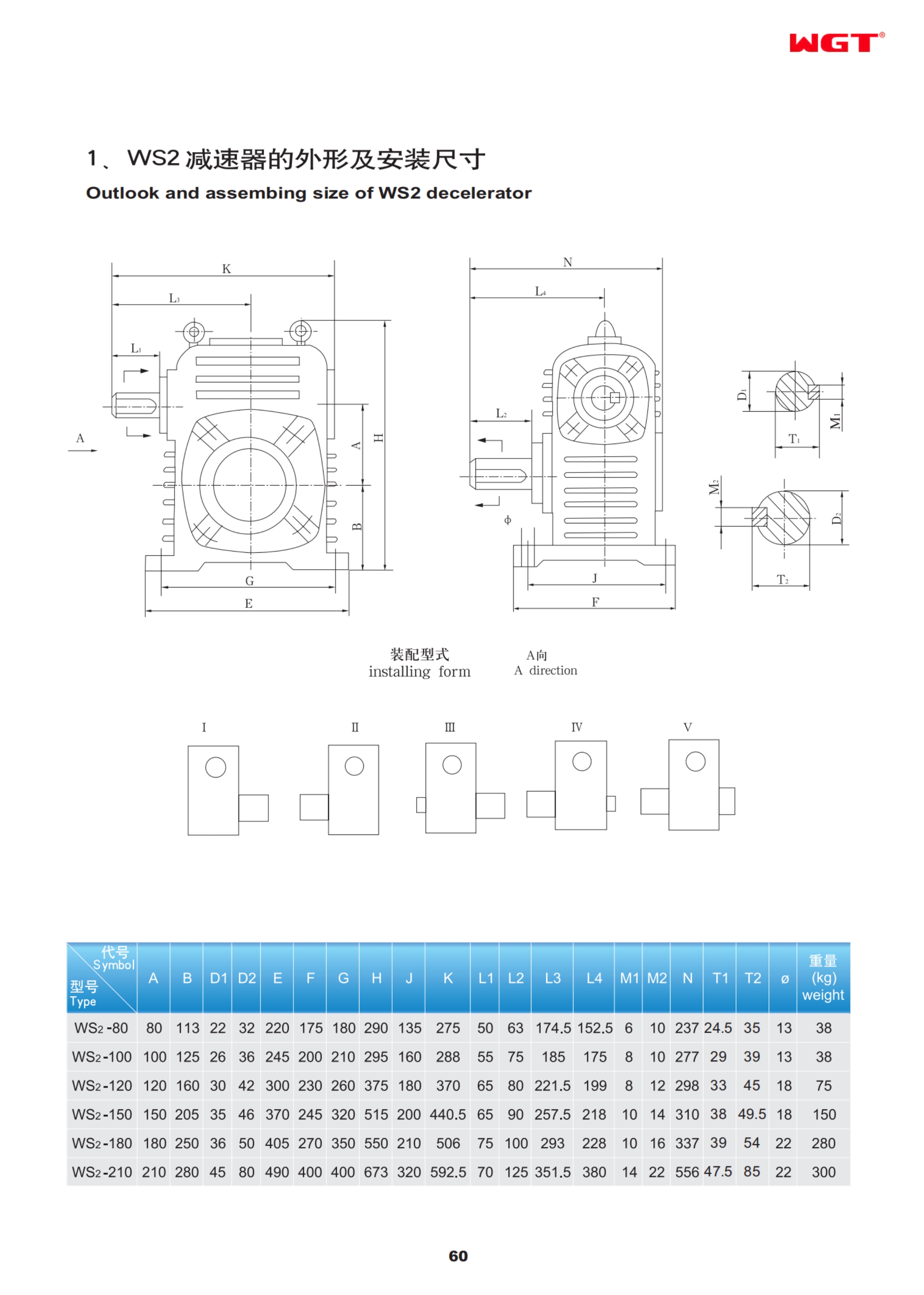

- WP series worm gear box

- NMRV series aluminum shell reducer

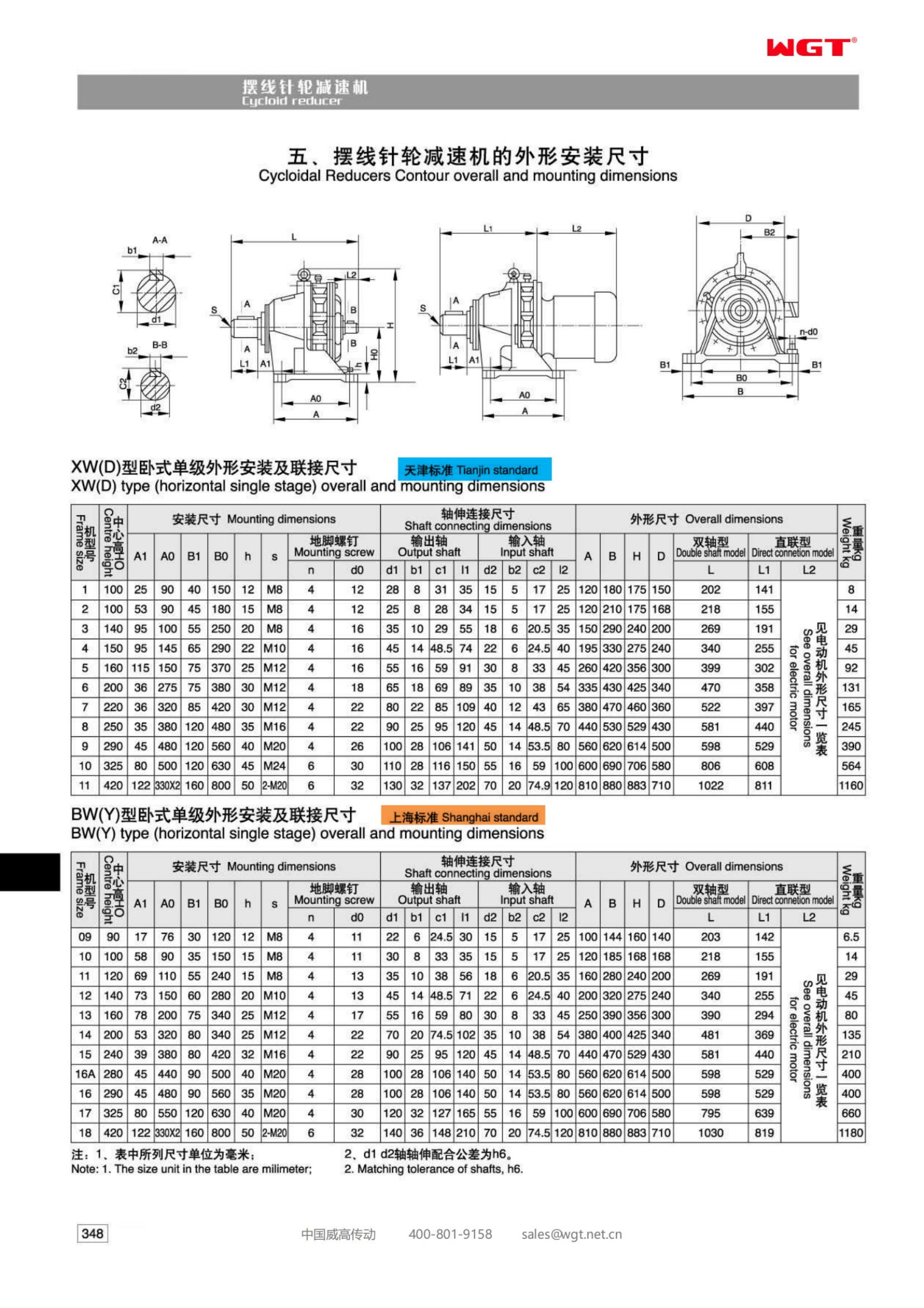

- B/X cycloid reducer

- ZQ ZD ZL ZS soft tooth surface cylindrical gear reducer

- ZSY ZLYJ DBY QJ ZD DC medium hard tooth surface cylindrical gear reducer

- T series spiral bevel gear reducer

- SWL JW JWB JWM series worm screw jack

- YHJ series non-gravity mixer special reducer

- SMR series shaft mounted reducer

- AC motor

- IEC Standard Motor

- Y2(YS YX3 MS) aluminum cylinder series high efficiency three-phase asynchronous motor

- YE3 series ultra-high efficiency three-phase asynchronous motor

- YBX3 series explosion-proof dust explosion-proof three-phase asynchronous motor

- YBBP series explosion-proof frequency converter motor

- RKSF series reducer high-efficiency motor

- GLF series high efficiency three-phase asynchronous motor

- High-efficiency three-phase asynchronous motor for YSF series axial fans

- Four series of high-efficiency motors

- YC_MC series single-phase capacitor start asynchronous motor

- YL_ML series double-value capacitor single-phase asynchronous motor

- YY(MY) series single-phase capacitor run asynchronous motor

- generator set

- Coupling

- Search Classes by Model

- [China Optical Network Supply Chain]CNFIBERNET

- Production Strength

- 3D selection system

- Electronic Catalogue

- News

- After-sale service

- FAQ

- Global case

- Online Message

- Contact Us